At Bakon Engineering, we offer premium system components that enhance pressroom efficiency—from fully automated ink distribution systems to energy-saving drying technology and intelligent roll-changing solutions. Our partnerships with leading global manufacturers like Technotrans, MEGTEC, and Pastex ensure that every component we install meets the highest standards in performance, automation, and safety.

With decades of experience in printing house infrastructure, we integrate systems that reduce downtime, optimize ink usage, recover valuable solvents, and ensure seamless roll transitions. Whether you’re looking to modernize your inking process, improve drying efficiency, or streamline roll changes, Bakon Engineering delivers ready-to-install systems backed by expert support. Our advanced systems & printing tech are tailored to improve efficiency, automation, and print quality in modern operations.

01

Technotrans Systems for Printing Machines

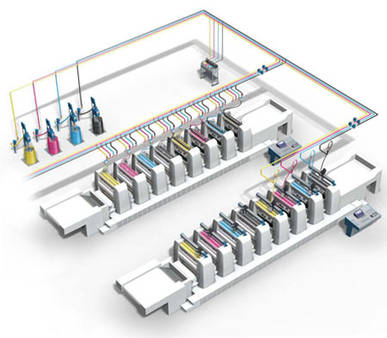

With centralized ink pumping systems, automation in ink distribution, cleanliness, and savings come together. Bakon is the company with the most installations in Turkey.

Bakon installs centralized ink pumping systems for automatic fountain filling in printing machines. These systems are connected to the ink fountains of the printing presses and ensure automatic ink refilling through sensors in the fountains.

Bakon has installed automatic Technotrans ink systems for many newspapers and major sheet-fed offset printing houses in Turkey.

Central Coating Control Units

Alpha.v Central Coating Circulation Unit

A cost-effective dispersion and UV coating circulation system designed for doctor blade or roller systems. It features two independently controllable electric pumps, air valves, hot water cleaning for residue removal, a remote-controlled display, and an integrated coating level sensor in the tank.

Some coatings require higher operating temperatures — for these applications, the Zeta.v unit has been developed.

Water Purification Systems

Alpha.r Water Purification Osmosis Unit

Professional printing companies know that water quality is one of the most critical factors directly affecting print quality. With the Alpha.r series purification systems developed by TECHNOTRANS, you benefit from:

Consistent water quality for better print results

100% pure water

Carbon pre-filtration

Conductivity measurement display

Integrated hardness dosing system

Easy installation and user-friendly operation

The Alpha.r system also supports digital printing presses with integrated dampening systems.

Dampening Solution Filtration Systems

TECHNOTRANS DAMPENING SOLUTION FILTRATION SYSTEMS

Captures particles down to 1 micron. Through a bypass line taken from the tank, it keeps the tank clean without affecting production. It is a compact two-stage filtration system based on a timeline. Recommended for 70×100 and larger printing presses.

Captures particles down to 1 micron. Filtration is provided via a bypass line taken from the tank. One Alpha.f unit is recommended per cooling circuit. In terms of capacity, it is suitable for 35×50 and 50×70 printing presses.

Basic.f:

A cost-effective three-stage filtration system capable of capturing dirt down to 5 microns. Designed for use in sheetfed offset press setups (35×50 / 50×70 / and 70×100 up to 4 colors) where Alpha.f and Beta.f filter systems are used. It extends the service life of dampening solution and ensures consistent print quality. Operates via a bypass method — when filters are fully clogged, the system automatically stops, but dampening solution circulation continues without interruption.

For heatset web presses:

Delta.f:

A ceramic filter system designed for web presses with spray bar dampening systems.

A filtration system designed for commercial heatset web printing presses. It uses a spinner mechanism to suction dirty and oily water from the tank surface and separates it using a centrifugal filtration process. Filter replacement is not required.

After extensive research and field testing, TECHNOTRANS developed the “ring band” system. Compared to other filter systems, Hydroflow is a more comprehensive offset ring-type filtration system with many advantages. It is adapted to the return line of direct dampening systems and purifies the returning dirty water.

Spray Bar Systems

TECHNOTRANS SPRAY BAR SYSTEMS

Deltaspray line:

Spray dampening units are a crucial component of web printing presses, playing a key role in ensuring reliable print quality and high process stability. These systems transfer dampening solution with controlled, high pressure. Each nozzle can be replaced without the need for tools. The symmetrically designed spray units are interchangeable, making installation and maintenance easy.

Alcohol Dosing and Replenishment Units

TECHNOTRANS ALCOHOL DOSING AND REPLENISHMENT UNITS

Alcosmart (AZR – R):

These alcohol control units with automatic calibration are the most precise digital systems for adjusting the desired isopropyl alcohol (IPA) level in the dampening solution using an infrared (IR) gas analysis sensor. The dosing range is between 0–15%, with a volumetric accuracy of ±0.5%. The system is unaffected by contamination, salts, air bubbles, or foam in the water.

Automatically regulates the desired amount of isopropyl alcohol (IPA) in the dampening solution. It operates with a volumetric accuracy of ±1%, with a dosing range of 3–15%.

These systems regulate the desired IPA level in the dampening solution using both mechanical and electronic methods. Various models are available. Accuracy ranges from ±1.5% to ±2%, and the dosing range is 5–15%.

Digidos.p:

A digital dampening solution dosing system that delivers precise dosing rates with high application safety and a margin of error as low as ±0.1%.

Ink Supply Systems

TECHNOTRANS INK SUPPLY SYSTEMS

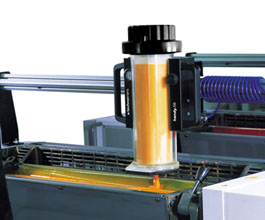

A nozzle containing a tube continuously moves across the ink fountain. When the ink level drops, it allows ink to flow from the tube into the fountain. Thanks to continuous low-level replenishment, fresh ink is constantly supplied, ensuring high print quality. Because there’s minimal ink reserve left in the fountain during ink changes, replacement is quicker and easier. Over 15,000 printing presses worldwide have been converted to ink cartridge systems by TECHNOTRANS. On newly manufactured presses, this system is now integrated as a fully automatic feature. The consumption of each InkLine unit can be measured electronically, and—where supported by certain press manufacturers—can be monitored directly from the press control console via a direct connection.

A simple system designed for sheetfed offset printing presses, adaptable to all brands and models. Using 2 kg ink cartridges, ink is pumped via a trigger mechanism. Even if partially used cartridges are removed for later use, the ink does not dry out or degrade.

The “Easy Ink Filling System” is designed for sheetfed offset presses. Compatible with all brands and models through custom kits, it feeds ink from 2 kg cartridges using compressed air and a push-button mechanism.

Professional, user-friendly, and reliable systems that provide continuous ink transfer to the fountains of sheetfed and web offset presses. High-performance pumps deliver ink into high-pressure-resistant tubes. When the ink level sensor mounted on the fountain detects a low level, the system automatically refills it. Optional consumption monitoring is also available.

A speed-controlled ink mixing system mounted directly on the ink fountains of the printing units. It prevents ink from drying and forming a skin on the surface, ensuring standard-quality printing while saving time and money.

A mechanical dosing pump that operates solely on water pressure—without electricity—to dose dampening solution additive proportionally based on water volume.

References

Heatset Printing

- DOĞAN OFSET YAY. VE MATB. AŞ.

- BİLTUR BASIM YAY. VE HİZM. A.Ş.

- UNİPRİNT BASIM SAN. VE TİC. A.Ş.

- ŞEDELE MATB. VE TİC. LTD. ŞTİ.

Sheetfed Offset

- BİLTUR BASIM YAY. VE HİZM. A.Ş.

- UMUR BASIM SAN. VE TİC. A.Ş.

- ABA MATBAA YAY. EĞİ. SAN. VE TİC. LTD.ŞTİ.

- LEVENT OFSET BASIM VE AMBALAJ SAN. A.Ş.

Newspapers

- HÜRRİYET GAZETECİLİK MATBAACILIK A.Ş.

- FEZA GAZETECİLİK A.Ş.

- HABERTÜRK GAZETECİLİK MATBAACILIK A.Ş.

- STAR MEDYA YAYINCILIK A.Ş.

- DÜNYA SÜPER WEB OFSET AŞ.

- T MEDYA BASKI TEKNOLOJİLERİ A.Ş.

- İHLAS GAZETECİLİK A.Ş.

02

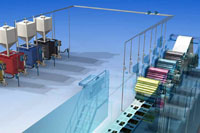

MEGTEC Systems

Expert solutions for industrial drying and solvent recovery systems.

REGENERATIVE THERMAL OXIDIZER (RTO) AFTERBURNER

The No.1 choice of Heatset and Coldset machine manufacturers for high performance:

MEGTEC Roll Stands, Ovens, and Afterburners

Types of MEGTEC Thermal Oxidizer Afterburners:

MEGTEC Thermal Oxidizer Afterburner – KATEC

MEGTEC Thermal Oxidizer Afterburner – Recirculated

MEGTEC Thermal Oxidizer Afterburner – Catalytic

MEGTEC Thermal Oxidizer Afterburner – WOS

MEGTEC Thermal Oxidizer Afterburner – Flameless Single Chamber RTO

MEGTEC Thermal Oxidizer Afterburner – CLEAN SWITCH

MEGTEC Thermal Oxidizer Afterburner – Single Rotary Valve RTO

Solvent Recovery:

Carbon Adsorbers

Biofilters and Biowashers

Dryers

Web Transport Systems

Application Areas of MEGTEC Thermal Oxidizer Afterburners:

Flexographic Printing

Rotogravure Printing

Chemical Industry

Automotive Industry

Wastewater Treatment

Odor Control

Graphic Arts

Roll Coating

Spray Booths

Pharmaceutical Industry

Petrochemical Industry

03

Pastex Reel Labels / Tabs

System components that ensure minimum downtime and maximum safety during reel changeover processes.

Nitto and Meatec Reel Splicing Tapes

Used in automatic reel stands during reel splicing.

Each tape type has a different function in the splicing process.

Aluminum reel splice label

Black reel splice label

Pastex Plus reel splice label

Phosphorescent reel splice label